Wholesale Sip Sealing Machine - IC Packaging Converting Machine – JKTech Detail:

Tray

Tape / Reel

Tube packaging

■ Automatic components loading, furling and sealing; Aoi marking & orientation inspection is optional.

■ Industrial PC controlled, easy to operate and programming.

■ Converting IC packaging from Tray to Tape or Tape to Tray, Tube to tray or Tape as needs.

■ Support 6~46mm tape width.

■ IC angle can be changed freely, pick and place with a high-speed Camshaft.

■ Optional function: Mark printing or CCD visual inspection.

■ Standard Auto-tray magazine design with compact size, and a short changeover time.

■ CE – Option.

■ Free sample testing program available.

Tape Sealing

NG Marking

Position Correction

Built-in auto-tray design, compact in size, all special aluminum and is easy to maintain.

Maximum 25 trays storage capacity.

Automatic tray replenishes.

Compatible with JEDEC Tray standard: 12.70x 5.35” inches

Specification:

If you are interested in our products, please email to Sales@jinke-tech.com

| Packaging speed: | 6000UPH |

| Packaging accuracy: | ±0.05 mm |

| Max. IC size Lx W: | 32 x 32mm |

| Max. Tape width: | 46mm |

| Loading: | Tube, Tape, Tray |

| Output: | Tape, Tray |

| CCD AOI inspection: | option |

| Auto-tray magazine: | standard and compatible with JEDEC spec |

| Language: | Chinese & English |

| Power supply: | 220v 1 phase, 50 Hz, <1KW |

| Compress air: | 0.4~0.6mpa, 45L/min |

| Footprint: | L040 x W750x H1530 mm |

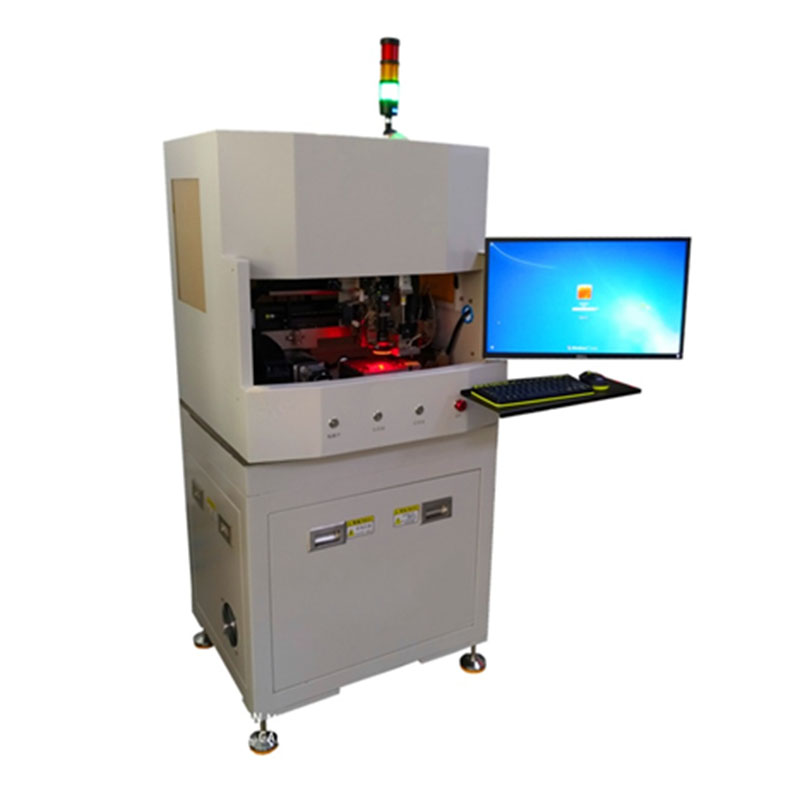

Product detail pictures:

Related Product Guide:

With this motto in mind, we've come to be one of quite possibly the most technologically innovative, cost-efficient, and price-competitive manufacturers for Wholesale Sip Sealing Machine - IC Packaging Converting Machine – JKTech , The product will supply to all over the world, such as: Italy, Macedonia, Georgia, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market. We are willing to cooperate with business friends from at home and abroad and create a great future together.

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.