Wholesale High-Precision Servo Fpc Punching - JKTECH Automatic V-Cutting Machine – JKTech Detail:

■ Compact in size with a high degree of automation, HMI interface, stepping & servo motors driving, simple to operate

■ De-paneling at one time for PCBAs design with a cross v-scoring

■ Touch screen operation, modularized change over, easy for maintenance

■ Equipped optic sensors inside to ensure human safe

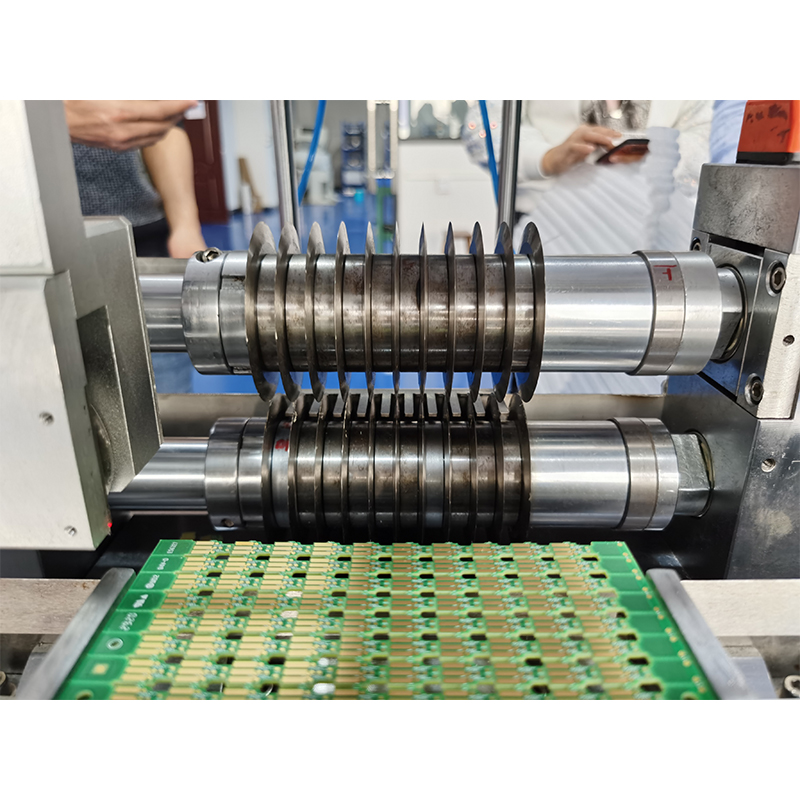

■ Unique & patent blade design with longer life-span and high accuracy cutting

■ Multi-blades design, minimized mechanical stress on SMT components, avoiding to make creaks on solder joints and broken the sensitive components

■ Standard SMEMA communication port, connect to a PCBA loader and unloader, it can be a fully automatic inline machine

■ Vacuum dust cleaner is selectable

■ CE is available

■ FOC. Sample test

If you are interested in our products, please email to Sales@jinke-tech.com

|

Model |

VCUT860INL |

|

Name |

Automatic V-Cutting Machine |

|

Size of the 1st blade module |

ϕ80mm×12mm×3mm @ 2~3pcs |

|

Size of the 2nd blade module |

ϕ80mm×12 mm×3mm -Customizable |

|

Size of Bottom straight blade |

L356*45*3mm |

|

Blade material |

Special DIE STEEL |

|

Blade brand |

Std: China-made, CAB (optional) |

|

Blade lifespan |

Std:1million times; CAB: 2 million times |

|

PCB thickness |

0.5-3.0 mm |

|

PCB Size (L/W mm) |

Min.5/5-Max.350/300 |

|

Driven mode |

Stepping motor, Servo motor(optional) |

|

Cutting speed |

Range 300mm-500mm/s |

|

Controlling system |

PLC + HMI |

|

Recipes |

100 Groups |

|

Power supply |

1 phase 220V 50hz |

|

Air supply |

4~6kgf |

|

Weight |

350kg |

|

Footprint L/W/H |

Approx. 1360 mm×800mm×1100mm |

Product detail pictures:

Related Product Guide:

Adhering into the principle of "quality, provider, performance and growth", we now have gained trusts and praises from domestic and intercontinental consumer for Wholesale High-Precision Servo Fpc Punching - JKTECH Automatic V-Cutting Machine – JKTech , The product will supply to all over the world, such as: Ukraine, UK, The Swiss, Ensuring high product quality by choosing the best suppliers, now we have also implemented complete quality control processes throughout our sourcing procedures. Meanwhile, our access to a large range of factories, coupled with our excellent management, also ensures that we can quickly fill your requirements at the best prices, regardless the order size.

We have been looking for a professional and responsible supplier, and now we find it.