New Arrival China Inline Pcb Roller Clean – PCBA Dust Cleaning Machine – JKTech Detail:

■ Used for cleaning PCB surface dust and eliminate electricity static

■ In-line automatic cleaning machine, save time and labor

■ Configurated two sets of standard electrostatic eliminator on the entrance and exit end of conveyor, completely eliminate ESD remains on the PCB surface and as the standard to ensure the highest safety operation running

■ Draw-out design, the cleaning roller can be drawn out, making it easier to maintenance and changeover

■ Process width: 50 ~ 490mm, PCB thickness: 0.1 ~ 5.0 mm

■ The height of the cleaning roller is precisely adjustable

■ Various spec of rollers available

01005: 0.4mm x 0.2mm

■ Standardized with supporting rollers at the bottom of the PCB to prevent PCB warping and minimize stress changes

■ Configured board jam sensor inside and alarm timely

■ Process flow direction switchable, std is L to R

■ Fully adjustable support system ensuring the boards being processed are held in contact with the top cleaning module regardless of width and or thickness. No board jam in all process

■ Sticky paper usage time pre-setting by the software to avoid the paper waste and keep a high-quality performance in all process

■ Option- Built-in vacuum system to remove dirt, board scraps, fibers, hairs and other foreign bodies on the surface before roller cleaning

■ Cleaning method: ESD brush + standard dust clean roller (ESD roller is optional)

ESD capability: <50V (meeting “Huawei-Mobile Phone” products requirement)

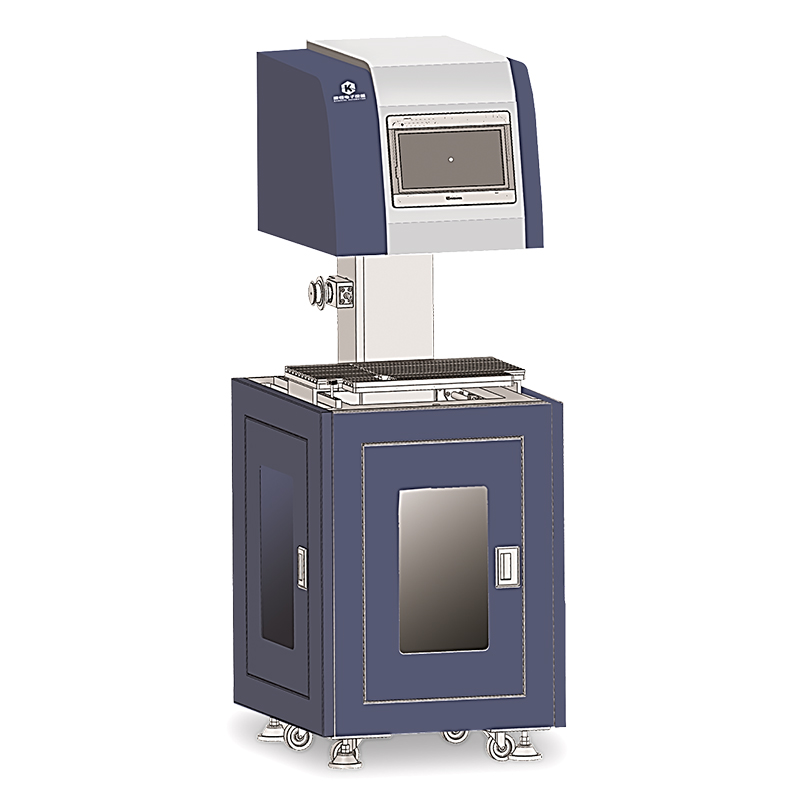

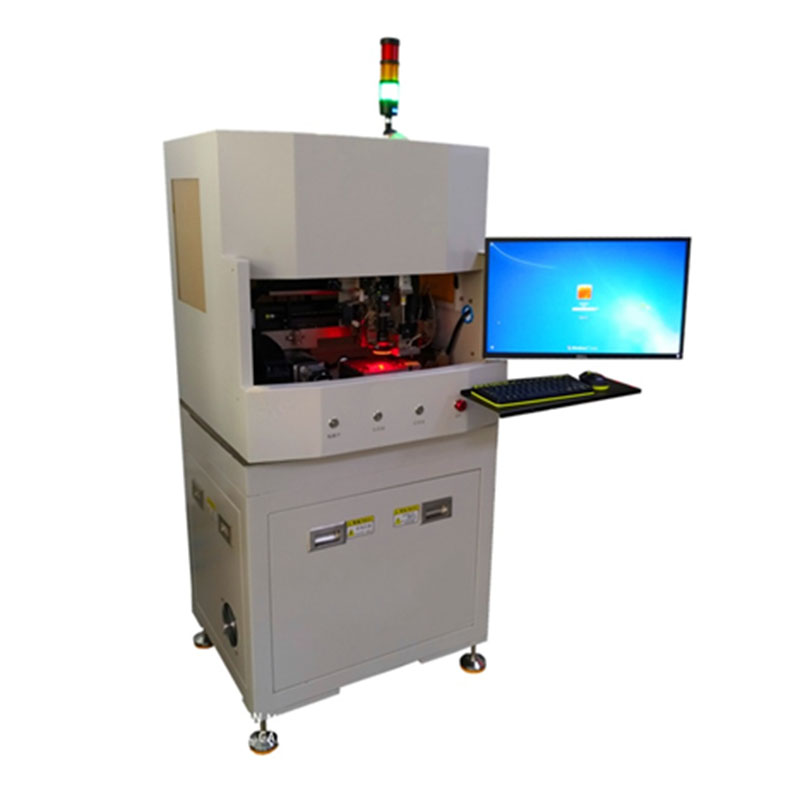

Product detail pictures:

Related Product Guide:

To be able to ideal satisfy client's requirements, all of our operations are strictly performed in line with our motto "High High-quality, Competitive Price tag, Fast Service" for New Arrival China Inline Pcb Roller Clean – PCBA Dust Cleaning Machine – JKTech , The product will supply to all over the world, such as: Bangalore, Philadelphia, Ghana, For anyone who is keen on any of our goods right after you view our product list, please really feel absolutely free to get in touch with us for inquiries. You are able to send us emails and contact us for consultation and we shall respond to you as soon as we can. If it's easy, you may locate out our address in our web-site and come to our business for far more information of our products by your self. We are always ready to construct extended and steady co-operation relations with any possible customers in the related fields.

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.