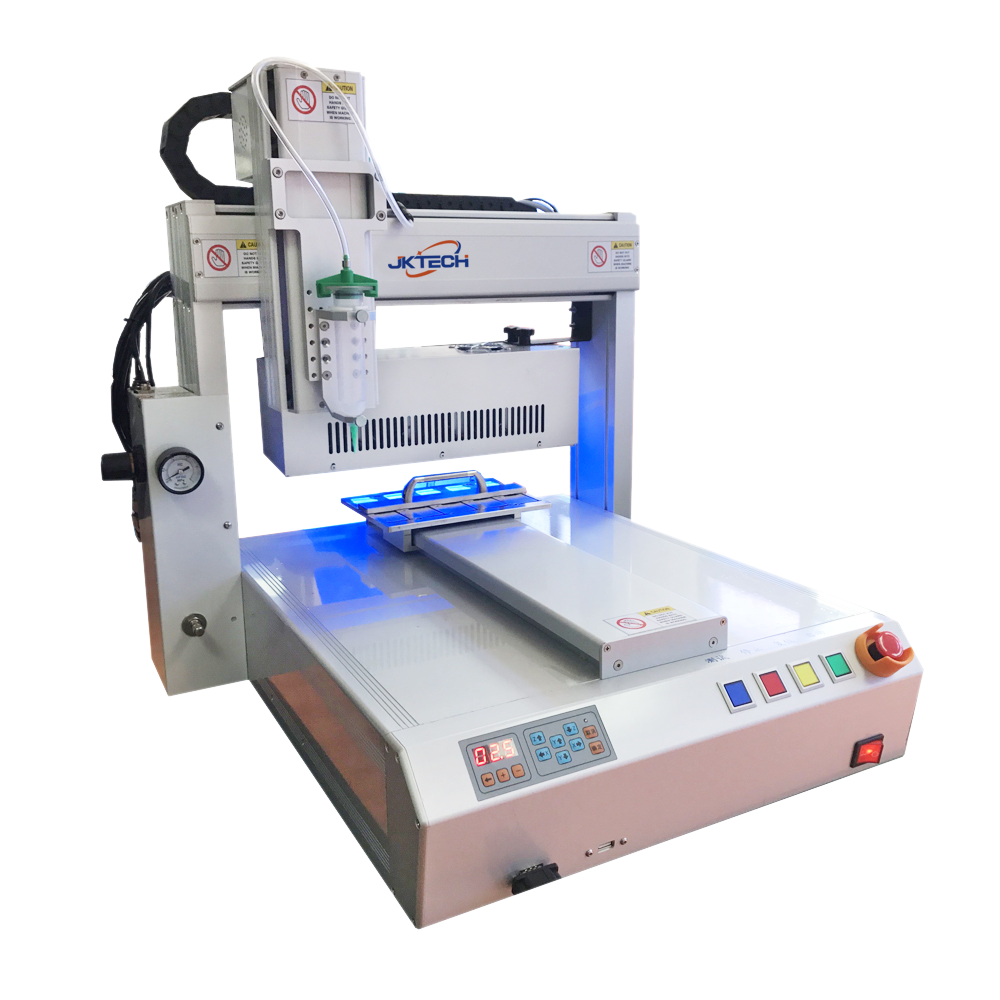

New Arrival China Inline Pcb Roller Clean – PCBA Dust Cleaning Machine – JKTech Detail:

■ Used for cleaning PCB surface dust and eliminate electricity static

■ In-line automatic cleaning machine, save time and labor

■ Configurated two sets of standard electrostatic eliminator on the entrance and exit end of conveyor, completely eliminate ESD remains on the PCB surface and as the standard to ensure the highest safety operation running

■ Draw-out design, the cleaning roller can be drawn out, making it easier to maintenance and changeover

■ Process width: 50 ~ 490mm, PCB thickness: 0.1 ~ 5.0 mm

■ The height of the cleaning roller is precisely adjustable

■ Various spec of rollers available

01005: 0.4mm x 0.2mm

■ Standardized with supporting rollers at the bottom of the PCB to prevent PCB warping and minimize stress changes

■ Configured board jam sensor inside and alarm timely

■ Process flow direction switchable, std is L to R

■ Fully adjustable support system ensuring the boards being processed are held in contact with the top cleaning module regardless of width and or thickness. No board jam in all process

■ Sticky paper usage time pre-setting by the software to avoid the paper waste and keep a high-quality performance in all process

■ Option- Built-in vacuum system to remove dirt, board scraps, fibers, hairs and other foreign bodies on the surface before roller cleaning

■ Cleaning method: ESD brush + standard dust clean roller (ESD roller is optional)

ESD capability: <50V (meeting “Huawei-Mobile Phone” products requirement)

Product detail pictures:

Related Product Guide:

We are experienced manufacturer. Wining the majority of the crucial certifications of its market for New Arrival China Inline Pcb Roller Clean – PCBA Dust Cleaning Machine – JKTech , The product will supply to all over the world, such as: Puerto Rico, Birmingham, Malta, With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in beauty and other industries. Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs.

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.