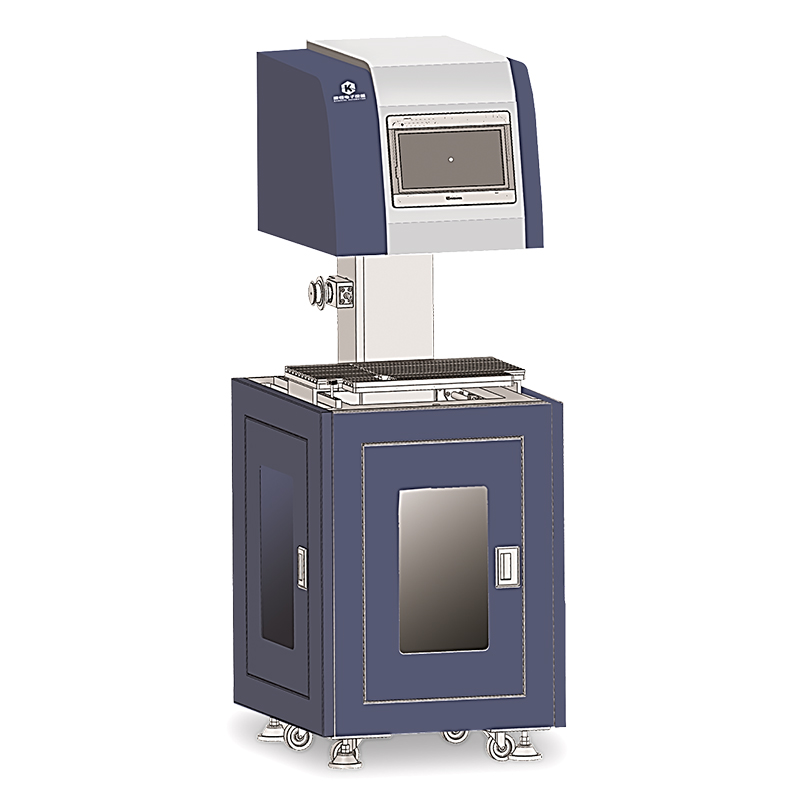

Manufacturer for Econ-Sd10ms - JKTECH Solder Dross Recovery Machine SD10MS – JKTech Detail:

■ Pure physical separation without using any chemicals.

■ Tin alloy separation rate is up to 98%

■ The recycled solder bar can be direct use for wave soldering

■ Compact in size, all stainless steel and is easy to maintain

■ Patented mixing and separation system for improved separation efficiency

■ Solder pot is made of corrosion resisting ss 316L material with has a long service life

■ The unit uses a “U” shape heater covered cast iron heating plate, which will avoid deformation

■ OMRON temperature controller and SSR relay ensure accurate temperature control and long service life

■ Machine will alarm when separated solder is in the cabin and reaches the full volume, this indicates to discharge the solder

■ Reclaim capacity is about 15KG/Hr. solder dross

■ Machine is equipped with 2 sets of molding tray, which are convenient for forming solder bars

■ Separated tin oxide ash will drop in separate box, for easy disposal

■ Asset payback period / ROI <6 months

■ CE is optional and available

■ 13 years of R&D and sales in WW

If you are interested in our products, please email to Sales@jinke-tech.com

|

Model |

SD800 |

SD10MS |

SD09F |

|

Power Supply |

3P 4¢ 380V @50HZ |

1phase 220v @50HZ |

1phase 220v @50HZ |

|

Connected Power |

5.8KW |

4.5KW |

2KW |

|

Normal Running Power |

1.8KW |

1.5KW |

1.0KW |

|

Bottom Tin Capacity of Mixing Zone |

100Kg |

70Kg |

10Kg |

|

Heating-up Time |

60mins |

60mins |

50mins |

|

Controlling System |

HMI+PID |

PID + Buttons |

PID + Buttons |

|

Reclaim Capacity |

30Kg/Hr. |

15Kg/Hr. |

6Kg/Hr. |

|

Solder Bar Molding Tray |

Automatic forming |

2 EA |

2 EA |

|

Net Weight Approx. |

500Kg |

110Kg |

45Kg |

|

Dimension (LxWxH mm) |

1800x1050x1600 |

680 x 850 x1050 |

500x250x650 140x330x390 |

Product detail pictures:

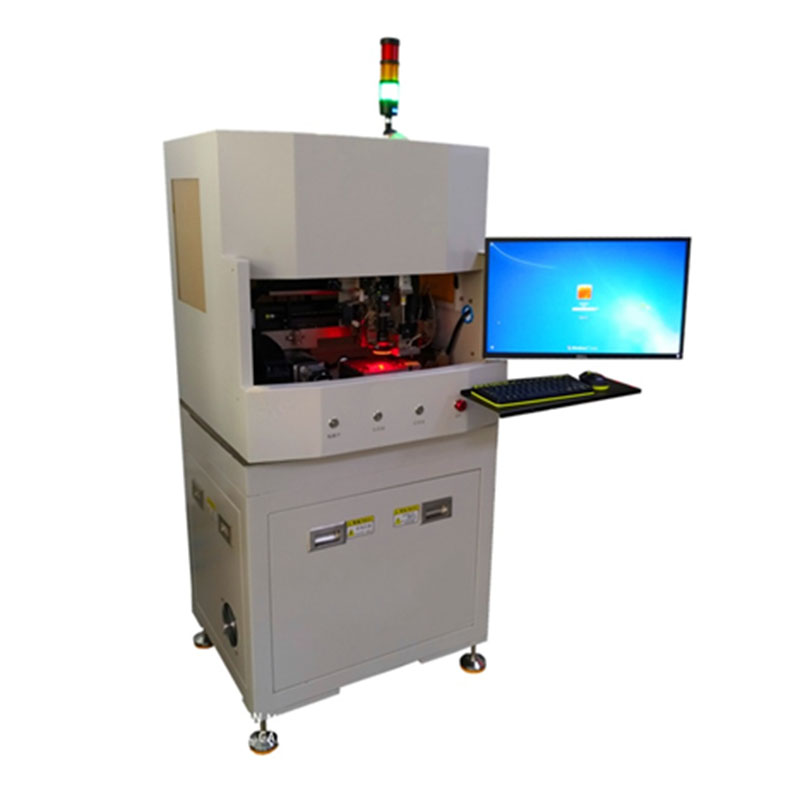

Related Product Guide:

We emphasize enhancement and introduce new solutions into the market just about every year for Manufacturer for Econ-Sd10ms - JKTECH Solder Dross Recovery Machine SD10MS – JKTech , The product will supply to all over the world, such as: Latvia, Gabon, Denver, Strong infrastructure is the need of any organization. We are backed with a robust infrastructural facility that enables us to manufacture, store, quality check and dispatch our products worldwide. To maintain smooth work flow, we have sectioned our infrastructure into a number of departments. All these departments are functional with latest tools, modernized machines and equipment. Owing to which, we are able to accomplish voluminous production without compromising upon the quality.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.