■ Applicable to the soldering of such products as Camera Modules, BGA re-balling, wafers, optoelectronic products, sensors, TWS speakers, …etc.

■ No flux soldering and minimized pollution process

■ Melted ball in the tip with no splash occurred

■ The amount of soldering is controllable and stable, meeting the requirements of the products with high speed, high frequency and high precision requirements

■ Consistent soldering quality and high first pass yield

■ Configured CCD visual position system

■ Able to Connect to a upper PCBA loader and unloader, to realize fully automatic production and save manpower

■ Fast heating and super-fast ball jetting speed up to 15k balls/h (PPH)

■ Varied diameter of solder ball available between φ0.30 to 2.0mm

■ Applied to the metal surface of tin, gold and silver with a yield rate>99%

■ CE marked

■ Free sample testing program available

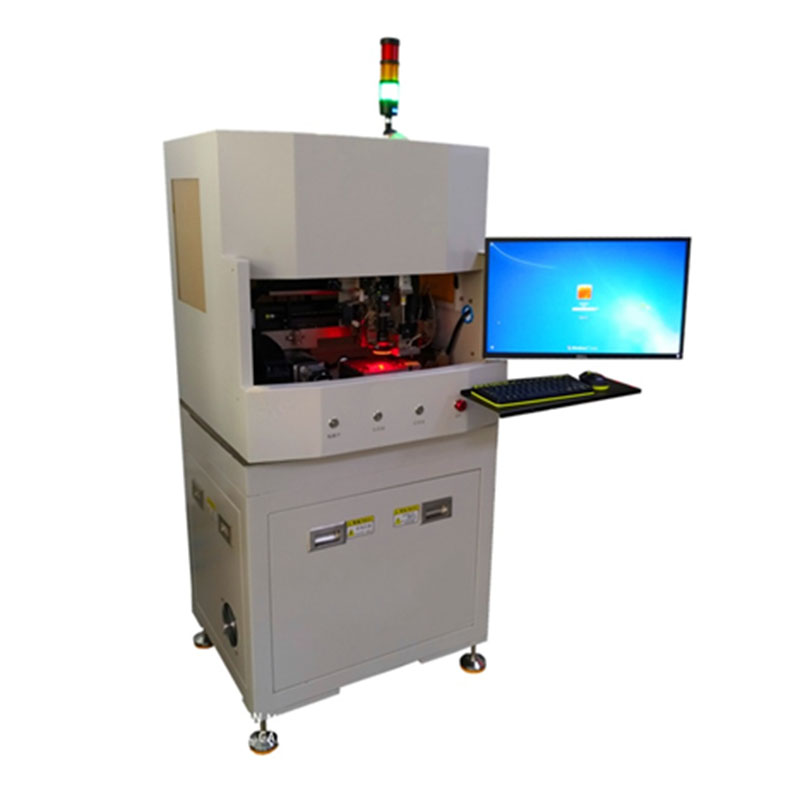

| Standard Model | JK-LBS200 |

| Laser power | 75W |

| Wavelength | 1064 nm |

| Fiber diameter | 200um-600um (optional) |

| Life span of laser source | >80,000Hrs. |

| Working area | 200x150mm (optional) |

| Solder ball diameter | φ0.30 to 2.0mm |

| Alignment system | CCD |

| Operation system | WIN10 |

| Exhaust system | Build-in smoke purifier |

| N2 supply | > 0.5MPa @99.999% |

| Power supply | 220V 50Hz, 10A |

| Footprint | Approx. 1000x1100x1650mm |