■ Superior and durable brands are selected for the motor and the integrated motor control system

■ Dry cutting and wet cutting are feasible according to the customer’s requirements

■ There will not generate large amount of heating during cutting process

■ It can achieve the cleaning of cutting line and anti-corrosion device has been assembled

■ Wire breaking sensor and sample cutting sensor are assembled for shut-down in time, ensuring the security

■ The machine adopts anti-corrosion materials, such as aluminum alloy, stainless-steel and plastic, so that the machine will not be easily rusted

■ The color touch panel with HMI interface makes the operation easy so as to control the cutting process and quality

■ Configured automatic winding device for easy wire winding, saving labor and time

■ CE marked

■ Free sample testing program available

PCB Cross section

PCBA Cross setion

Metal, Ceramics cross

If you are interested in our products, please email to Sales@jinke-tech.com

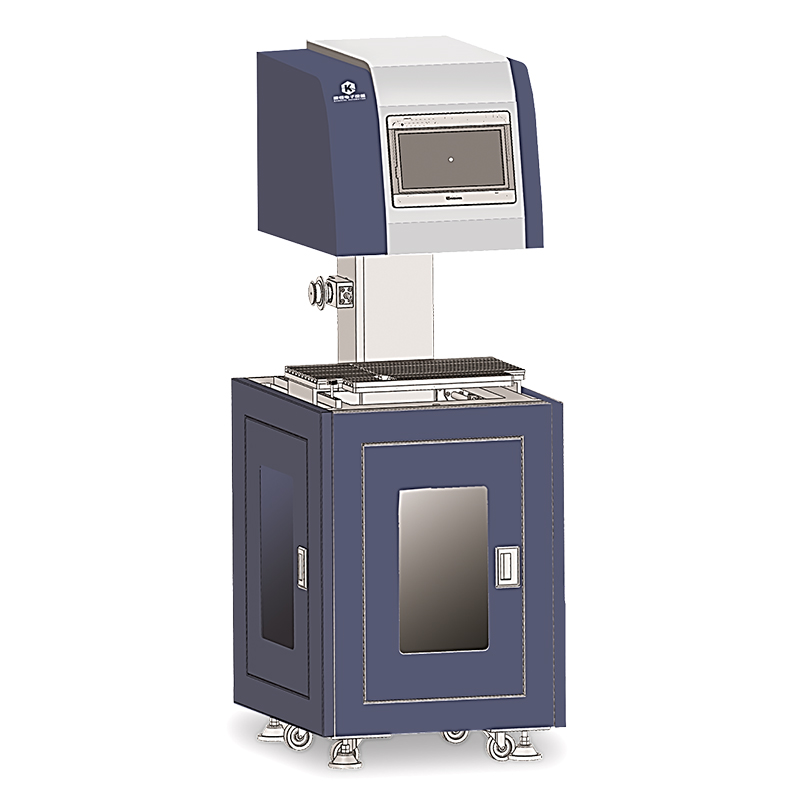

| Model | JK-DWS500 |

| Overall dimension | Approx. 770 X670 X1600mm |

| Height of operation table | 1065mm |

| Rated power | 400W |

| Rated voltage | 220V |

| Diameter of wire | 0.2mm-0.45mm |

| Length | 20000mm |

| Diameter of drive wheel | 240mm |

| Cutting tensile | Force of gravity/constant force |

| Cutting speed | 0-4m/s |

| Cutting direction | Cutting from both front and back |

| Cutting range | ≦ 15kg,≦ 500 × 160 ×160 mm |

| Cutting stroke | 160 mm |

| Cleaning way of cutting line | Mechanical scroll washing |

| Control method | Color touch panel |

| safety measures | Safety door with protection switch |