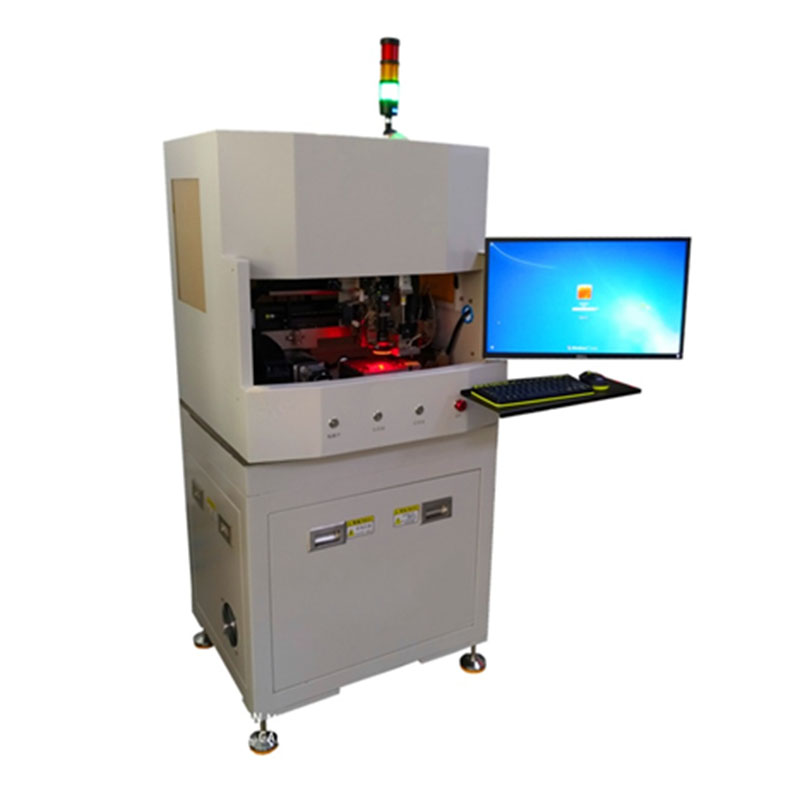

2021 wholesale price Roller Clean - PCBA Dust Cleaning Machine – JKTech Detail:

■ Used for cleaning PCB surface dust and eliminate electricity static

■ In-line automatic cleaning machine, save time and labor

■ Configurated two sets of standard electrostatic eliminator on the entrance and exit end of conveyor, completely eliminate ESD remains on the PCB surface and as the standard to ensure the highest safety operation running

■ Draw-out design, the cleaning roller can be drawn out, making it easier to maintenance and changeover

■ Process width: 50 ~ 490mm, PCB thickness: 0.1 ~ 5.0 mm

■ The height of the cleaning roller is precisely adjustable

■ Various spec of rollers available

01005: 0.4mm x 0.2mm

■ Standardized with supporting rollers at the bottom of the PCB to prevent PCB warping and minimize stress changes

■ Configured board jam sensor inside and alarm timely

■ Process flow direction switchable, std is L to R

■ Fully adjustable support system ensuring the boards being processed are held in contact with the top cleaning module regardless of width and or thickness. No board jam in all process

■ Sticky paper usage time pre-setting by the software to avoid the paper waste and keep a high-quality performance in all process

■ Option- Built-in vacuum system to remove dirt, board scraps, fibers, hairs and other foreign bodies on the surface before roller cleaning

■ Cleaning method: ESD brush + standard dust clean roller (ESD roller is optional)

ESD capability: <50V (meeting “Huawei-Mobile Phone” products requirement)

Product detail pictures:

Related Product Guide:

Well-run gear, qualified revenue workforce, and superior after-sales companies; We've been also a unified huge loved ones, anyone persist with the organization benefit "unification, determination, tolerance" for 2021 wholesale price Roller Clean - PCBA Dust Cleaning Machine – JKTech , The product will supply to all over the world, such as: Denmark, Costa Rica, Sierra Leone, Due to the stability of our items, timely supply and our sincere service, we are able to sell our merchandise not only over the domestic market, but also exported to countries and regions, including the Middle East, Asia, Europe and other countries and regions. At the same time, we also undertake OEM and ODM orders. We will do our best to serve your company, and establish a successful and friendly cooperation with you.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.